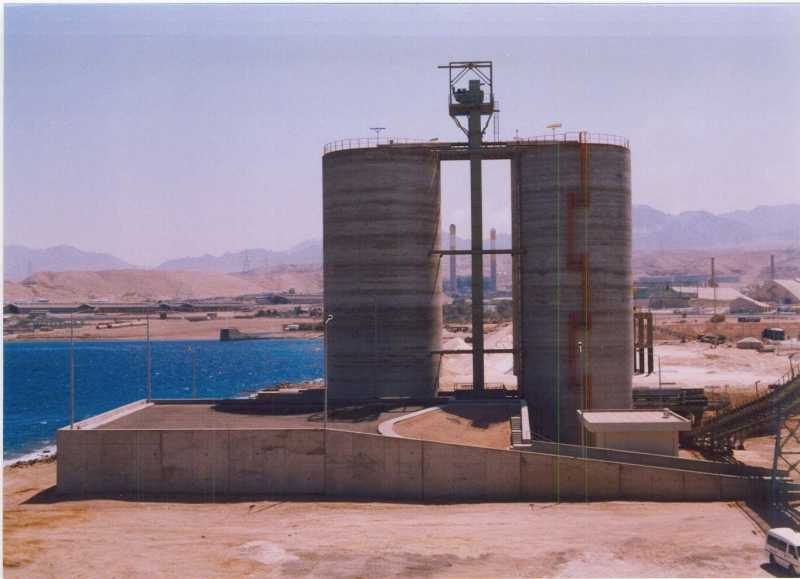

Concrete Silos and Tanks

MgO Sinter Silos

Client/ Owner : Jordan Magnesia Co.- Location : Jordan

- Period : 2002/2003

- Designers and consultants : Designer : Engineering Consultation Office (Egypt) Consultant : JACOBS Engineering Inc., Ireland

More Information :

The scope of works included the design and the detailed design, fabrication, manufacturing, procurement, construction, commissioning, testing and handing over a completely functional system to receive, store and dispatch the MgO sinter materials produced by the Magnesia Dead Sea Plant. The plants includes two reinforced concrete silos of 6000 ton total capacity, the silos walls were built using the slipforming technology of Bygging, Sweden. Sinter MgO receiving bin is lined to resist abrasion, the materials from the receiving bin is transferred to the lower head of the bucket elevator through a 150 ton/hour belt conveyor, the system includes all instrumentations and automated control requirements such as nucleonic weighting system at export belt conveyor, ultrasonic measurement of level and flow and control panel including programmable logic controllers with necessary modifications to interface with other users of JFI export conveyor.